Rotary Piston Vacuum Pumps

A rotary piston pump is a kind of hydraulic pump. The doing work pistons lengthen in the radial route symmetrically all over the drive shaft.

A rotary piston pump is a self-preparing reversible positive relocation pump that can convey high volume oils and thick liquids, such as tars and fuel proficiently. Rotary piston pumps commonly handle up to 20,000cst and temperatures up to 300°C.

A rotary piston pump works by a piston sliding to and fro along a rotor groove, maneuvering fluid into the pump’s delta. The rotor works like a rotary valve empowering the pump to self-prime. Two direct determined pistons are working in twin chambers. The piston moves towards the Center of the pump when close to the pump bay, and as it moves towards the outlet of the pump, it moves along the rotor ousting the fluid through the outlet.

Main Working Principle of Rotary Vacuum Pumps

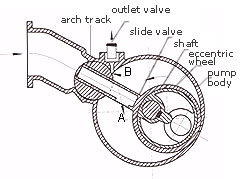

The vacuum pump body is furnished with an unclogger ring 4 and an offbeat wheel 3. The erratic wheel is fixed on the pole 2, and the pole concurs with the middle line of the vacuum pump body. A rectangular unclogger bar 5 is masterminded on the unclogger ring, which can slide all over and swing left and right in the semi-roundabout unclogger control rail 7. Hence, the vacuum pump body is isolated into two chambers, an and B by the unclogger ring and the unclogger pole. During the activity of the vacuum pump, because of the occasional difference in the volume of the chamber an and chamber B, the gas persistently enters the pull chamber with steadily expanded volume; simultaneously, with the decrease of the volume of the fumes chamber, the gas is packed, and the gas is released through the fumes valve.

The above is the working principle of a rotary piston vacuum pump in China. If there is an issue, alter and supplant the warming segment of the vacuum bundling machine, if you don’t mind reaching us!

These sorts of piston pumps are characterized through the following benefits:

- higher efficiency

- substantial stress

- reduced flow and strain ripple

- lower noise degree

- quite substantial load at lowest velocity resulting from the hydrostatically balanced parts attainable

- no axial internal forces on the drive shaft bearing

- higher reliability

Because of the hydrostatically balanced elements it really is possible to make use of the rotary piston pump with various hydraulic like mineral oil, biodegradable oil, HFA (oil in water), HFC (water-glycol), HFD (synthetic ester) or cutting emulsion.

Rotary Piston Pump Applications

- Hydraulic Equipment

- High Pressure Units

- Check Rigs

- Hydraulic Suspension Manage

- Injection Molding

- Wind Energy

Rotary Piston Pumps – Choose Best Hydraulic Pump

Rotary piston pumps are certain types of hydraulic pumps. These pumps come loaded with pistons. Obviously, these piston vacuum pumps play an important role when it comes to accomplishing a task. When it comes to choosing these hydraulic types of pumps, you can easily find lots of suppliers/manufacturers. But you are advised to go with the right supplier.

Since you want to end up with the best piston pump, you need to take a few things into consideration. So, let’s check out how you can choose the best pumps.

What Are the Specifications?

When you decide to choose vacuum pumps of this type, you need to take specifications of the same into consideration. It’s a fact that the performance of a machine largely depends on its specifications. The same natural rule also applies when it comes to choosing a piston pump. So, you first need to go through specifications or features of your chosen pump.

However, it’s true that you should go with a pump incorporated with plenty of features, but it doesn’t mean that you should go with a complicated option. So, you need to look for an easy to use machine that can help you unveil its incredible features with least effort. Should you choose to ignore the features or specs of a pump, you will end up with a wrong option.

Durability Matters

When it comes to choosing best rotary piston pumps online, you aren’t supposed to ignore one thing i.e. durability. Yes, you will never like to spend your hard earned money on buying the same type of vacuum piston pump again and again. Instead, you would like to go with a durable option. Choosing a durable machine simply means you can save money indirectly. It’s often seen that many people avoid taking this point into consideration. Thus, they end up spending money on buying the product again and again.

If you don’t want to spend money on buying the same type of vacuum pumps again and again, you need to confirm the durability of the pump.

Can I Easily Operate It?

However, it’s true that you need to go with a device incorporated with innovative technology, but it doesn’t mean that you should ignore the importance of easiness. If you won’t be able to operate a device, you won’t be able to get the desired results out of the same. So, before making a final decision, you first need to confirm whether you can easily operate the pump you choose or not.

There is no doubt that you would like to go with a vacuum pump loaded with innovative technology, but it doesn’t mean that you want to end up with a complicated system. Instead, you would like to choose a machine that can easily be operated. Going with an easy-to-use mechanism of pump can help you make a solid choice.

Operating principle and features:

The series HGL, HG pump is a kind of single-stage and single-cylinder rotary piston vacuum pump. It is greatly improved series H rotary piston pump and includes four patents; its general capabilities have a great improvement.

Rotary piston vacuum pump is a sort of vacuum production equipment suitable for pumping ordinary gases and condensable gases(when a gas ballast used). The pump must be fitted with appropriate accessories if gas is rich in oxygen, explosive, corrosive to ferrous metal, chemical reactive with vacuum pump oil.

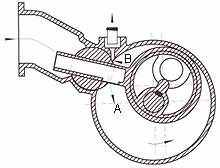

Operation principle show in working principle graph: A rotary piston with slide valve across ecentric wheel driven by shaft within the housing. Piston pole can slide and swing freely in arch track. The whole pump chamber is divided into chamber A and chamber B by piston. When shaft rotates the volume of chamber A and chamber B are changed repetitively, so that pumping purpose could be achieved.

The series HGL, HG pump can be a backing pump when combined with another high vacuum pump as well as operate singly. It is widely used in vacuum smelting, vacuum drying, vacuum impregnation and high vacuum simulation testing,etc.

Performance Parameter:

| Type | Ultimate Pressure | Total Pressure | Pumping Speed | Inlet Diam | Outlet Diam | Noise Level | Motor Power | Cooling Water Consumption | Weight |

| (Pa) | (Pa) | (L/S) | (mm) | (mm) | dB(A) | (Kw) | (L/min) | (Kg) | |

| HGL-150 | 0.3 | 2 | 150 | 100 | 80 | 79 | 11 | 450 | 680 |

| HGL-70 | 0.3 | 2 | 70 | 80 | 63 | 78 | 5.5 | 350 | 500 |

| HG-150 | 0.3 | 2 | 150 | 100 | 80 | 79 | 15 | 700 | 860 |

FAQ

1. How long does a vacuum pump last?

The vacuum pump is designed to last a lifetime, but this will usually not happen due to the harsh conditions in which it has to operate.

2. How do you test a vacuum pump?

Attach the micron gauge directly to the vacuum pump via the 1/4″ connection and verify that the pump can achieve a vacuum level of 100 microns or less. A good quality pump will quickly achieve levels or below 50 microns.

3. Does a vacuum pump add horsepower?

In general, a rotay piston pumps in China is an added benefit to any engine that is high performance enough to create a significant amount of blow-by. A vacuum pump will, in general, add some horsepower, increase engine life, keep oil cleaner for longer.

Find more size vacuum pumps?