Roots Vacuum Pumps

Roots Vacuum Pump Principles, Applications etc

Operating Principle and Features:

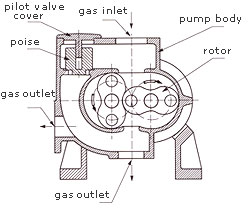

The series SYF roots vacuum pump is with overflow valve. The figure-of-eight rotors are counter-rotating at a constant speed inside the pump housing for suction and exhaust of gas. Two rotors are supported by two bearings and synchronized by a gear, which ensures these two rotors in certain relative positions. They are near to one another and to the housing without actual contacting, so lubrication is unnecessary in the working housing. The carefully balanced operating parts and high precision bevel wheels ensue the pump be operated stably and continuously under the condition of high-pressure difference. Dynamic seal part use our patent technology and imported oil seals, the vibration amount of shaft on the shaft seals is controlled to less than 0.02 mm.

A gravity valve is installed between the suction and exhaust part of the pump. The function of the gravity valve is as follows, when the pressure difference between the suction and exhaust part is over the weight of the valve, the valve opens automatically, which makes the pressure difference always keep in a fixed controllable value, the value is the allowable highest pressure difference to ensure the pump work normally and so that in fact, the roots vacuum pump with overflow valve is a kind of overload self-protective pump.

Series SYF roots vacuum pump with overflow valve has substantially higher speed at relatively lower inlet pressure and it is possessed overload self-protective function. Because it is a pump of dry clearance seal construction, if a certain pumping speed rate and an ultimate vacuum need to be obtained, it is necessary to supply a lower inlet pressure for reducing the back flow, therefore, a pump must be backed in use, roots vacuum pump should be started soom after its inlet pressure reaches a permissible value for economization.

It is permit to select different kinds of pump as the backing pump for factual requirements, such as oil seal pump and liquid ring vacuum pump. When pumping the gas containing large amount of vapor, the liquid ring vacuum pump is the ideal backing pump.

| Model | Ultimate Pressure | Pumping Speed | Pressure Diff.at Overflow Valve | Inlet Diam. | Outlet Diam. | Motor Power | Recommended Backing Pump | Cooling Water Consumption | Weight |

| (Pa) | (L/S) | (Hpa) | (mm) | (mm) | (Kw) | (L/min) | (Kg) | ||

| SYF-30 | 3×10-² | 30 | 52 | 50 | 40 | 0.75 | 2H-8 | / | 85 |

| SYF-70 | 3×10-² | 70 | 52 | 80 | 50 | 1.1 | 2H-15 | / | 110 |

| SYF-70D | 3×10-² | 70 | 48 | 100 | 100 | 1.5 | 2H-15 | 20 | 220 |

| SYF-150 | 3×10-² | 150 | 48 | 100 | 100 | 2.2 | 2H-30 | 25 | 220 |

| SYF-300 | 3×10-² | 300 | 58 | 150 | 150 | 4 | 2X-70,2H-70 | 30 | 310 |

| SYF-600 | 5×10-² | 600 | 32 | 200 | 200 | 7.5 | H-150,HGL-150 | 35 | 790 |

| SYF-1200 | 5×10-² | 1200 | 44 | 250 | 200 | 11 | H-150,HGL-150 | 40 | 950 |

| ZJP-1800 | 5×10-² | 1800 | 32 | 250 | 250&200 | 15 | 2-HG150,ZJP600/HG150 | 50 | 1200 |

| ZJP-2500 | 5×10-² | 2500 | 44 | 320 | 320&250 | 18.5 | 2-HG150,ZJP600/HG150 | 60 | 1500 |

Things to Look for When Choosing Roots Vacuum Pumps Online

Roots vacuum pumps come incorporated with an overflow valve. A root vacuum pump contains 8 rotors, which is established in a counter-rotating position. These rotors are usually supported by powerful two bearings as well as synchronized by an innovative gear. It means that it helps two rotors functioning in certain positions.

If you are looking for these types of vacuum pumps, you can easily find plenty of stores online. But the actual problem arises when you simply get confused about recognizing a right supplier or manufacturer. Thus, you need to get rid of this confusion as soon as possible. For this, you need to take stated below points into consideration.

Why Do You Need Roots Vacuum Pumps?

Whether you are going to choose an innovative machine or service, you would always like to go with something that you really need. It’s a fact that you won’t like to spend your time and money on choosing a product that you really don’t need. It means that you would like to go with a machine that can cater your requirements. The same rule applies when it comes to choosing vacuum pumps.

So, you are advised that before making a deal, you first need to evaluate your requirements of choosing pumps. If you notice that choosing pumps can help you make your job easier, you need to go with the same. When you are aware about your vacuum pump requirements, you can certainly make a right deal.

Understand the Functionality of Vacuum Pumps

It’s another important point that you need to keep in mind when it comes to recognizing best roots pumps. When you decide to choose a machine, you first need to evaluate its functionality. Since the performance of a device largely depends on its functionality, you need to evaluate the overall functionality of the same.

It’s usually observed that most individuals/retailers want a long-lasting and high-performing pump. Thus, they need to understand the functionality of vacuum pumps. So, there are different types of pumps available online. You need to go through the functionality of each and every vacuum pump to make a final decision.

Evaluate Quality of Materials

Whether you are looking for vacuum pumps or something else, you first need to go with a quality option. It’s a fact that use of quality materials simply influences the durability of the product. So, if you are looking for durable vacuum pumps online, you first need to confirm whether it is made of quality materials or not.

In case of ignoring materials used in manufacturing roots pumps, you won’t be able to end up with the right choice. Obviously, you won’t like to regret your own decision. Thus, you would like to choose a vacuum pump made of the best quality of materials.

Best Manufacturers

The easiest way to choose pumps whether online or offline is to recognize the best manufacturers. Since there are different types of manufacturers, you may get a bit confused about recognizing a right manufacturer.

So, you need to go through reviews about top vacuum pump manufacturers online.

Applications of Roots Vacuum Pumps

With the advancement of vacuum application, there are numerous sorts of Roots vacuum pump. The roots vacuum pump’s pumping velocity has transformed from a couple of liters for every second to several thousand and a large number of liters every second. As per the Roots vacuum pump’s working standard, the roots vacuum pump can be fundamentally separated into two kinds, specifically gas catch pump and gas move pump. With the vacuum innovation in the creation and logical exploration, the weight scope of its application is getting more extensive and more extensive. Most vacuum pumps should be made out of a few roots vacuum pumps to pump together to meet the creative and logical examination measures’ prerequisites. Since the working weight territory engaged with the vacuum application division is vast, it is difficult to finish any Roots vacuum pump. It is reasonable for all working weight ranges. Various sorts of Roots vacuum pumps must be utilized by multiple working weight ranges and diverse working prerequisites. To utilize helpfully and address the issues of different vacuum measures, separate roots vacuum pumps are consolidated by their presentation necessities and applied as units. The generally used roots vacuum pumps incorporate dry screw vacuum pump, water ring pump, responding pump, slide valve pump, rotating vane pump, roots pump, and dispersion pump. These pumps are the necessary primary pumps in utilizing vacuum innovation in different enterprises of the public economy. As of late, with the continuous and fast advancement of China’s economy, the downstream application industry identified with roots vacuum pumps keeps a quick development force. Simultaneously, under the joint draw of the nonstop extension of the application field of Roots vacuum pump and different components, the roots vacuum pump industry in China has accomplished a continued, steady and fast turn of events.

Know More About Roots Vacuum Pump

The roots vacuum pump is a mechanical vacuum pump with a couple of soled rotors pivoting simultaneously and rapidly. This pump can’t be suctioned alone. The front stage should be outfitted with an oil seal, water ring, etc., to deplete the air legitimately. Its structure and working guidelines are like roots blowers. When it works, its pull port is associated with the primary pump of the emptied vessel or vacuum framework. There is no contact between the rotor and the rotor or between the rotor and the pump shell, and the freedom is commonly 0.1-0.8mm; oil isn’t needed. The rotor profile incorporates a roundabout circular segment, involute, cycloid, and so on. The involute rotor pump has high volume usage proportion and is simple to guarantee machining exactness, so the rotor profile is generally involute. The turning pace of the Roots vacuum pump can be as high as 3450 ~ 4100 rpm; the pumping rate is 30 ~ 10000 L/S (1 L = 10-3 m3); the cutoff vacuum: the single-stage is 6.5 × 10-2 PA, the twofold stage is 1 × 10-3 PA.

The Roots vacuum pump’s cutoff vacuum depends not just on the structure and assembling precision of the pump itself, but also on the breaking point vacuum of the front stage pump. To improve the pump’s breaking point vacuum, a roots pump can be utilized in the arrangement. The working guideline of the roots pump is like that of a Roots blower. Because of the rotor’s ceaseless pivot, the extricated gas is brought into the space V0 between the rotor and the pump shell from the air channel and afterward released through the fumes port. As the V0 space is wholly shut after the pull, the pump pit’s gas isn’t packed and extended.

Be that as it may, when the head of the rotor turns the edge of the fumes port, and the space V0 is associated with the fumes side, given the high gas pressure at the fumes side, a piece of the gas streams over into the space V0, which makes the gas pressure abruptly increment. As the rotor keeps on turning, the gas leaves the pump. In the hole of the roots pump, two “8” molded rotors are vertically introduced on a couple of equal shafts. A couple of rigging belts with a transmission proportion of 1 move backward coordinated turn with one another. There is a sure hole between the rotors, the rotors, and the inward mass of the pump packaging, which can understand the rapid activity. Book from our roots vacuum pump suppliers.

FAQ

1. What are the advantages of roots vacuum pumps?

There is a more massive pumping speed in the broader pressure range.

The rotor has good geometrical symmetry, so the vibration is small, and the operation is stable.

The compression is relatively low, and the effect of hydrogen extraction is poor.

2. What is the ultimate pressure in a vacuum pump?

Ultimate pressure pult is the lowest pressure of a blank-flanged vacuum pump under defined conditions without gas inlet. At maximum pressure, the usable pumping speed will be zero. It is a theoretical value. The lowest pressure, which can be achieved in a vacuum vessel, will be determined by—pumping speed.

3. What is the best vacuum pump oil?

Triple distilled pump oil is transparent and is designed for an ultimate vacuum of 0.6 microns (6 x 10-4 torr). Hydrotreated oil is a high-end pump oil designed for high vacuum applications, such as industrial and science.

Find more size vacuum pumps?

Roots Vacuum Pump, Roots Vacuum Pump in China, China Roots Vacuum Pumps, China Roots Vacuum Pumps Suppliers