Vacuum Pump

What is a vacuum pump?

Vacuum pumps are devices that create a vacuum environment by removing air or other gases from a space, typically to achieve a pressure lower than atmospheric pressure. They are used in various applications, including scientific research, industrial processes, and manufacturing.

Vacuum pumps can be classified based on their operating principles and applications. Some common types of vacuum pumps include the following:

1. Roots vacuum pump: Roots vacuum pump is a variable displacement vacuum pump. Its working principle is to use a pair of counter-synchronously rotating blade-shaped rotors to rotate in the pump chamber to compress the gas, thereby achieving the purpose of pumping air. Roots type vacuum pump has the advantages of high pumping speed, low ultimate vacuum, and low energy consumption, so it has been widely used in the industrial field. It can be used in petroleum, chemical industry, plastics, pesticides, steam turbine rotor dynamic balancing, aerospace space simulation and other fields.

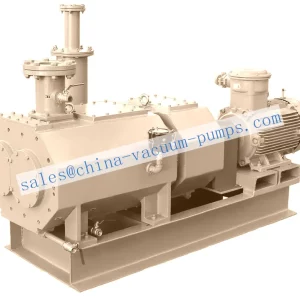

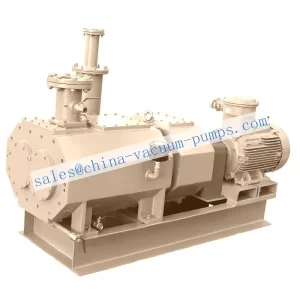

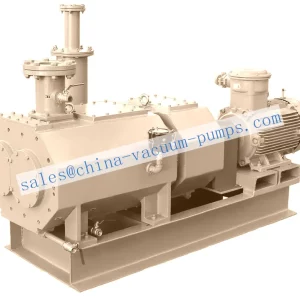

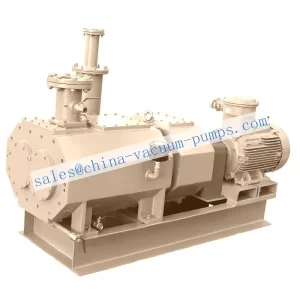

2. Screw Vacuum Pump: The screw vacuum pump is a pump that uses the screw rotor to rotate and compress in the pump chamber to transport gas. Its working principle is to compress and discharge the gas in the pump chamber through the rotation of a pair of screw rotors, thereby achieving air extraction and exhaust. Screw vacuum pumps have the advantages of simple structure, easy maintenance, and high reliability.

3. Rotary vane vacuum pump: Rotary vane vacuum pump (Rotary Vane Vacuum Pump) is a common and commonly used vacuum pump type. It consists of the rotary vane, outlet valve, pump chamber, and oil seal. Its main working principle is to use centrifugal force and inertia force to generate a vacuum in the pump chamber through the rotating vane. During the rotation process, a variable-volume working chamber is formed between the rotary vane in the pump chamber and the pump chamber wall, which is constantly changing. The rotary vane is affected by centrifugal force and the gas pressure in the pump chamber, slides along the pump chamber wall, and passes through the pump. The outlet discharges the gas. Rotary vane vacuum pumps have the characteristics of simple structure, small size, lightweight, and reliable operation. They are widely used in laboratories, industrial manufacturing and scientific research fields.

4. Reciprocating Vacuum Pump: A reciprocating vacuum pump is a device that uses the principle of reciprocating motion to generate a vacuum. It usually consists of a cylinder, piston, valve, and pump chamber. When the piston reciprocates in the cylinder, the gas in the pump chamber is compressed and discharged, creating a vacuum at the pump outlet. The pumping rate and vacuum degree of a reciprocating vacuum pump can be adjusted by changing the stroke and frequency of the piston.

Reciprocating vacuum pumps have the advantages of simple structure, easy operation, high reliability, and low maintenance costs. It can be used in various situations where a vacuum needs to be generated, such as industrial production, laboratories, vacuum drying, food processing, and other fields. Reciprocating vacuum pumps are suitable for applications with lower vacuum requirements, such as the extraction of air and water vapor.

5. Liquid ring vacuum pump: The liquid ring vacuum pump is a low vacuum pump that uses liquid as the working medium. Its working principle is to use the centrifugal force generated when the impeller rotates to throw the liquid outward to form a crescent-shaped liquid ring. The liquid ring forms a crescent with the inner wall of the pump shell. A shaped working chamber sucks gas from the suction port and discharges it to the exhaust port through compression. Liquid ring vacuum pumps are usually divided into two types: water ring vacuum pumps and oil ring vacuum pumps, of which water ring vacuum pumps are the most widely used. Liquid ring vacuum pumps have the advantages of simple structure, easy operation, high reliability, and low maintenance costs. It can be used in various situations where low vacuum needs to be generated, such as the chemical industry, pharmaceutical, food processing, plastics, and other fields.

High Quality Vacuum Pump for Sale

-

Hot Sales 380/450V 3KW LC1200 Roots Booster Pump

-

Hot sales Roots booster pump 380/450V 2.2KW LC500

-

Hot sales Booster pump Vacuum auxiliary pump 380/450V 3KW LC1200 Roots booster vacuum pump

-

Hot sales LC250 380/450V 2.2KW Roots booster pump Vacuum auxiliary pump Booster pump

-

High Capacity Roots Vacuum Booster Pumps for Vacuum Distillation LC250 2.2KW

-

Hot sales 220-240/380-415V/460V three phase 7.5KW LC2600 Roots booster vacuum pump

-

500 m3/h LC500 Roots Vacuum Pump Booster Use in Petroleum/Chemical Engineering/Medicine/Pharmacy/Food/Spinning/Daily

-

Hot Sale Refrigerant Rotary Vane Vacuum Pump Two Stage Vacuum Pump

-

Oil Sealed Rotary Vane Vacuum Pump for Vacuum Metallurgy Vacuum Welding

-

2X-4A Portable Vacuum System Medical Oil Lubricated Rotary Vane Vacuum Pump

-

2X Series Industrial Vacuum Pump Oil Sealed Rotary Vane Vacuum Pump

-

2X-70A Single Stage Belt Drive Vacuum Pumps Oil Rotary Vane Vacuum Pump

-

2X-15 Rotary Vane Vacuum Pump Sliding Rotary Vane Vacuum Pump

-

Wholesale 2X-15 Oil Sealed Rotary Vane Vacuum Pump Silent Magnetic Pump

-

Factory Price 2X-8 Rotary Vane Vacuum Pump for Vacuum Coating

-

Factory Price Oil Sealed Rotary Vane Vacuum Pump Silent Vacuum Pump

-

Hot Selling Vacuum Pump Unit Reciprocating Vacuum Pump for Vacuum Evaporation

-

Food Vacuum Pump Reciprocating Vacuum Pump for Vacuum Drying

-

WLW 100 Vertical Reciprocating Vacuum Pump Mobile Industrial Vacuum Pump System

-

Vertical Oil Free Dry Industrial Vacuum Pump WLW 200 Vacuum Pump Machine

-

WLW Series Vertical Oil Free Reciprocating Vacuum Pumps for the Vacuum Distillation

-

Industrial Vacuum Pump System WLW 150 Reciprocating Vacuum Pump Price

-

Wholesale Price High Pressure Industrial Oxygen Gas Transfer Vacuum Pump Reciprocating Vacuum Pump

-

70 Pumping Speed Medical Low Noise Mini Piston Reciprocating Vacuum Pump For Molten Steel Treatment

-

Factory Price WLW Vertical Portable Corrosion-resistant Oil-free Piston Reciprocating Vacuum Pump

-

One Year Warranty 380V 14.75 HP 150 L/S Rotary Piston Mechanical Oil Free Reciprocating Vacuum Pump

-

High Quality Advanced Oil-free Lubrication 380V 15KW 200L/S Vertical Reciprocating Piston Vacuum Pump

-

LGB Air Cooled No Oil Dry Screw Vacuum Pump Oil Less Dry Screw Vacuum Pump

-

Factory Price Industrial Screw Vacuum Pump Stainless Steel Single Vacuum Screw Pump

-

Hot Selling Screw High Pressure Vertical Vacuum Screw Pump Dry Screw Vacuum Pump

-

Professional Precision 200 Pumping Speed IP55 Protection CNC Oil Dry Screw Vacuum Pump

-

One Year Warranty LGB-300 50HP 300L/S Variable Frequency Electric Screw Vacuum Pump

-

New Energy Saving Environmental Product Air-cooled Oil-free Industrial Screw Vacuum Pump

-

Wholesale Portable Speed Adjustable Multi-stage Vacuum Systems Oil-free Screw Vacuum Pump

-

Support After-sale Service Multi-stage Screw Vacuum Systems Pump Electric Screw Vacuum Pump

-

Factory Price Industrial Double Stage Screw Vacuum Pump Oil Free Screw Vacuum Pump

-

IP55 Protection Customizable Screw Vacuum Pump Low Pressure Electric Brake Dry Screw Vacuum Pump

-

Sifang Vacuum Equipment Customized LGB-300 2 Stage Dry Type Oil-free Screw Vacuum Pump

-

OEM ODM Customized Industrial Oil-Free Air Cooling Electric Brake Screw Vacuum Pump

-

Metallurgy Chemical Industry 2BE Single-Stage Single-Action Structure Liquid Water Ring Vacuum Pump

-

2BE Series Compact Structures Energy Saving Liquid Ring Vacuum Pumps Water Ring Vacuum Pump

-

High Performance Simple Structure Liquid Water Ring Industrial Vacuum Pump For Building Materials Industry

-

Single-Stage Single-Action Structure Liquid Water Ring Vacuum Pump For Building Materials Electrical

-

Simple Structure Design Multipurpose Single-Stage 2BE Liquid Ring Water Ring Vacuum Pump

-

Single Stage Multi Function Water Ring Vacuum Pump For Extract Non-Solid Particles

-

Factory Price Customized High Efficiency Stainless Steel 2BE Liquid Ring Water Ring Vacuum Pump

-

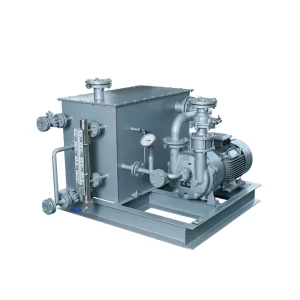

2BV5110 Liquid Ring Vacuum Pump Water Recirculation Vacuum Pump Unit

-

2BV5131 Portable Vacuum Pump Liquid Ring Vacuum Pump Unit for Food Industry

-

Professional Supplier Building Materials Electric 2 Stage Vacuum Air Pump Unit

-

Custom 2 Stage Vacuum Treatment Pump 2BV5110 Water Ring Liquid Ring Vacuum Pump

-

Strength Factory Electric Space-Saving 2BV 5110 Two Stage Roots Water Ring Vacuum Pump

-

VSP 150 Series Dry Screw Vacuum Pump

-

VSP 200 Series Dry Screw Vacuum Pump

-

VSP 300 Series Dry Screw Vacuum Pump

-

VSP 400 Series Dry Screw Vacuum Pump

-

VSP 800 Series Dry Screw Vacuum Pump

-

VSP 1000 Series Dry Screw Vacuum Pump

-

VSP 1500 Series Dry Screw Vacuum Pump

-

VSP 3000 Series Dry Screw Vacuum Pump

-

MB 100 Roots vacuum pump

-

MB 200 Roots vacuum pump

-

MB 400 Roots vacuum pump

-

MB 540 Roots vacuum pump

-

MB 720 Roots vacuum pump

-

MB 850 Roots vacuum pump

-

MB 1600 Roots vacuum pump

-

MB 2000 Roots vacuum pump

-

MB 1200 Roots vacuum pump

-

MB 2700 Roots vacuum pump

The difference between screw vacuum pump and rotary vane vacuum pump

Operating Principle:

Screw Vacuum Pump: This type operates using two parallel, helical screws (rotors) rotating in opposite directions. The gas enters the pump and is trapped between the screw threads and the pump housing. As the screws rotate, the trapped gas is transported along the screw and compressed before being discharged.

Rotary Vane Vacuum Pump: It contains a rotor with vanes that are slotted into it. The rotor is mounted off-center in a cylindrical housing. As the rotor spins, the vanes slide in and out, creating chambers of varying sizes. Gas is trapped in these chambers, compressed, and then expelled.

Design and Construction:

Screw Pump: Typically more complex in design, these pumps have fewer moving parts and no internal lubrication in the gas path. This design minimizes contamination risk and maintenance.

Rotary Vane Pump: Simpler in design but often requires internal lubrication, which can lead to potential contamination of the vacuum with oil vapors. Regular maintenance is needed to replace vanes and oil.

Performance and Efficiency:

Screw Pump: Generally more efficient at handling larger volumes of gas and maintaining a consistent vacuum level, especially in harsh environments. They can operate continuously at higher pressures.

Rotary Vane Pump: Efficient for low to medium vacuum ranges but may face challenges in sustaining high vacuum levels for extended periods. They are more sensitive to particulates and vapors in the gas stream.

Application Suitability:

Screw Pump: Ideal for industrial applications requiring a clean and dry vacuum, like electronics manufacturing, vacuum drying, or packaging. They are also suited for handling corrosive gases.

Rotary Vane Pump: Common in laboratory settings, HVAC servicing, and applications where a deep vacuum is needed, such as refrigeration servicing and some types of scientific research.

Maintenance and Operational Cost:

Screw Pump: Typically have a higher initial cost but lower maintenance requirements and longer lifespan.

Rotary Vane Pump: Lower initial cost but higher maintenance needs due to wear and tear on the vanes and the need for regular oil changes.

Screw Vacuum Pump

Rotary vane vacuum pump

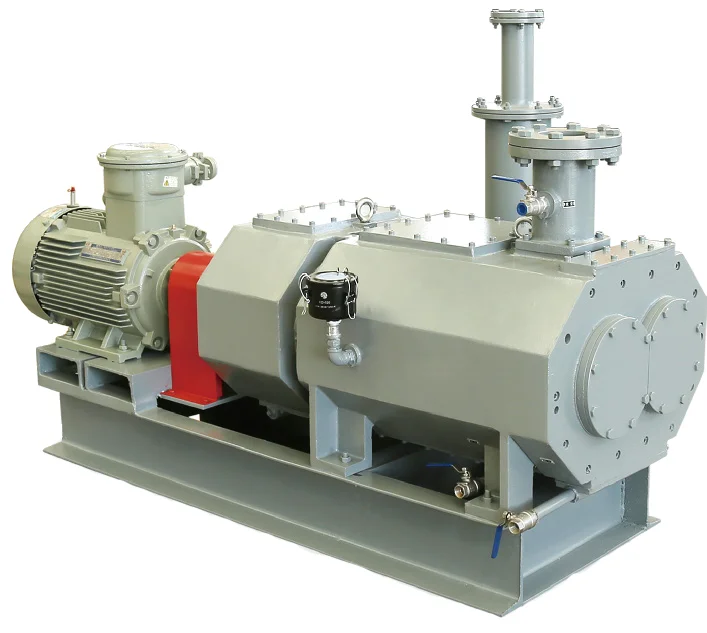

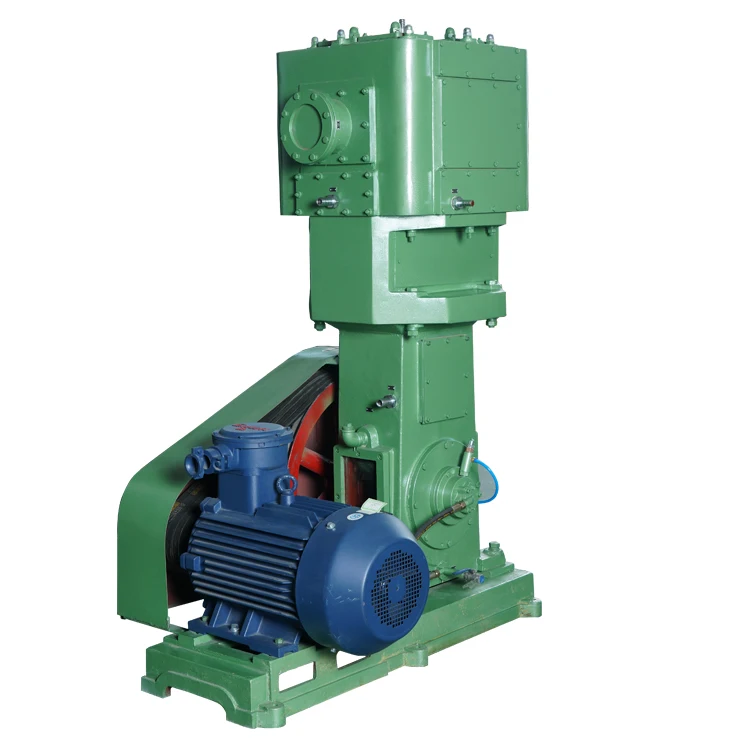

The difference between Roots vacuum pump and reciprocating vacuum pump

Operating Principle:

Roots Vacuum Pump: This is a type of positive displacement pump, known for its two symmetrically shaped rotors rotating in opposite directions. The rotors don’t come into contact with each other or the pump housing, which allows for high-speed operation. The pump traps the gas between the rotors and the housing, then moves it from the inlet side to the outlet side without compressing it.

Reciprocating Vacuum Pump: Also a positive displacement pump, it uses pistons (often in a cylinder) to compress and displace the gas. The piston moves back and forth (reciprocates) in the cylinder, drawing in gas through an inlet valve during the expansion stroke and discharging it through an outlet valve during the compression stroke.

Design and Construction:

Roots Pump: Characterized by a simple, robust design with minimal moving parts, leading to lower maintenance requirements. It lacks internal compression, meaning it often needs to be paired with another pump for initial evacuation.

Reciprocating Pump: More complex in design with more moving parts (pistons, cylinders, valves), which can lead to higher wear and tear and thus, more maintenance.

Performance and Efficiency:

Roots Pump: Efficient for medium to high vacuum levels. They are often used in combination with other pumps, as they can greatly increase the pumping speed of the system. However, they are not effective at creating a vacuum initially.

Reciprocating Pump: Generally good for creating a low to medium vacuum. They can achieve a higher ultimate vacuum compared to Roots pumps alone but are usually slower in pumping speed.

Application Suitability:

Roots Pump: Commonly used in industrial applications where a significant volume of gas needs to be pumped quickly, such as vacuum furnaces, semiconductor processing, and coating systems.

Reciprocating Pump: Suitable for applications requiring a deeper vacuum, such as laboratory use, refrigeration, and air conditioning system servicing, and in some industrial processes.

Noise and Vibration:

Roots Pump: Tends to operate more quietly with less vibration, due to the lack of internal compression and minimal contact between moving parts.

Reciprocating Pump: Can be noisier and have higher levels of vibration due to the reciprocating motion of the pistons.

Maintenance and Cost:

Roots Pump: Lower maintenance due to simpler design and lack of internal compression, but higher initial cost.

Reciprocating Pump: Requires regular maintenance due to wear on pistons and valves, but generally less expensive initially.

Roots vacuum pump

Reciprocating Vacuum Pump

Advantages of using a vacuum pump

Improve production efficiency: The vacuum pump improves production efficiency by removing gas during the production process, eliminating the obstruction of gas, and allowing materials to flow smoothly.

Improve product quality: In the fields of food, medicine, chemical industry, etc., products are easily affected by bacteria and impurities in the air. Using a vacuum pump can avoid contact with air, thus ensuring the purity and quality of the product.

Prevent oxidation: Some materials are prone to oxidation reactions in the air. Using a vacuum pump can prevent materials from contacting oxygen in the air and prevent oxidation of materials.

Energy saving: During the operation of the vacuum pump, the energy consumption of the equipment can be reduced, thereby achieving the effect of energy saving.

Protect the environment: The use of vacuum pumps can reduce gas emissions, reduce environmental pollution, and help protect the environment.

Blog

Custom Design

As a service to our customers, we offer extensive manufacturing experience and talent to meet the special needs of custom parts. Our in-house engineering team has extensive experience in designing and custom engineering solutions to meet your requirements. If you don’t see what you’re looking for in our standard range, please inquire about custom options.