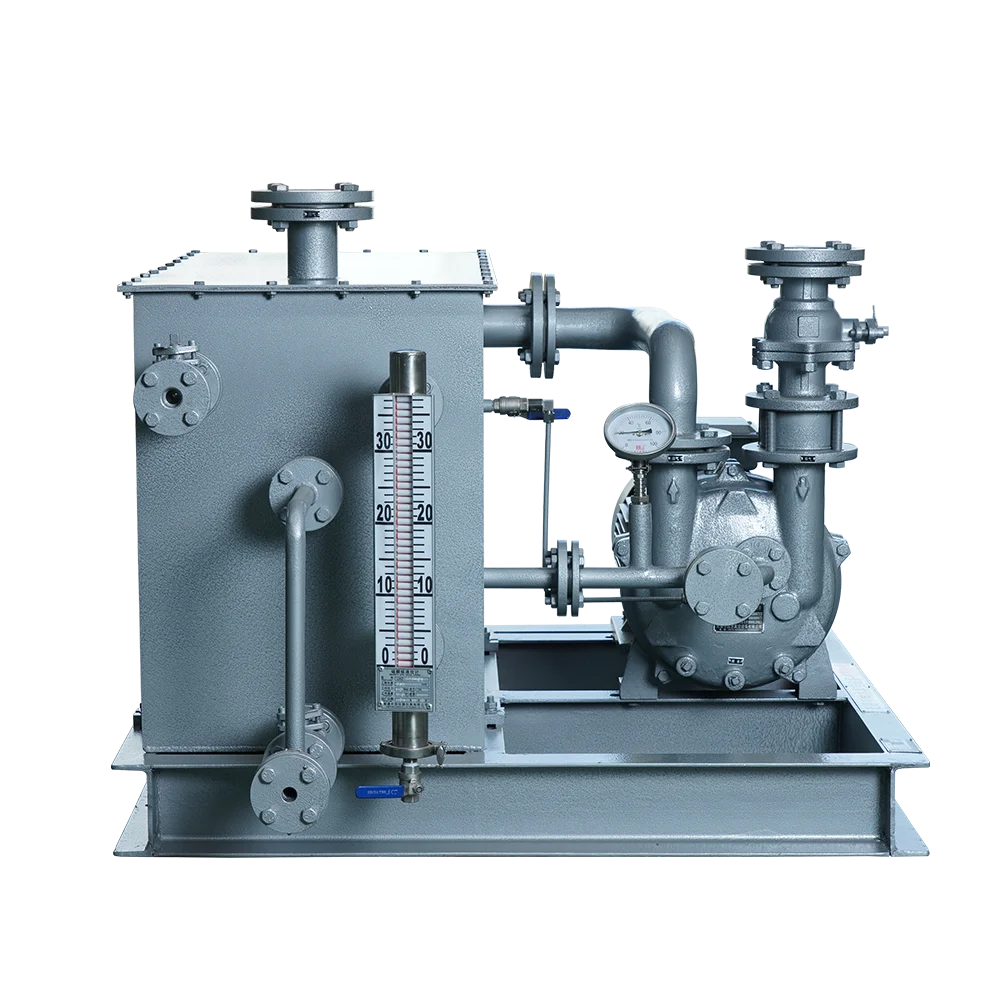

2BV5131 Portable Vacuum Pump Liquid Ring Vacuum Pump Unit for Food Industry

As one of the China vacuum pump manufacturers, suppliers, and exporters of mechanical products, We offer China vacuum pumps and many other products.

Please get in touch with us for details.

2BV liquid ring vacuum pump is mainly composed of pump body, rotor, impeller, suction port, exhaust port and other parts. Among them, the rotor and impeller are usually integrated and are called eccentric rotors. When the rotor rotates, the eccentric rotor drives the impeller to rotate in the pump chamber, forming a liquid ring similar in shape to the pump chamber. The volume of the liquid ring changes as the rotor rotates, thereby completing the process of gas suction, compression and discharge.

The structure and components of 2BV liquid ring vacuum pumps mainly include the following parts

Pump body: The pump body is the main body of the pump and is usually made of cast iron or steel. It is the supporting structure of the whole pump and provides the necessary strength and stiffness.

Rotor and impeller: The rotor and impeller are usually made of cast iron or steel and are connected together. The rotor is connected to the motor through the drive shaft, and the impeller rotates with the rotor to compress the gas.

Liquid ring: The liquid ring is formed by the liquid that is sealed in the pump and covers the outer wall of the impeller. It is composed of water or other suitable liquids and plays a role in sealing and lubrication.

Sucking and exhausting device: The sucking and exhausting device includes the suction port and exhaust port, which are connected to the pipeline system. Gas enters the pump through the suction port and exits through the exhaust port.

Lubrication system: The lubrication system includes oil storage, oil pump, oil cooler, oil filter and other components. It is responsible for lubricating the bearing and driving part of the pump to ensure normal operation.

Installation and maintenance of 2BV liquid ring vacuum pumps

Installation: Before installation, check whether all parts of the pump are damaged or loose, and whether all connections are complete and tightened. Confirm the installation position and check whether there are obstacles around the installation site that affect the operation of the pump. When installing, pay attention to aligning the pump with the motor to ensure that they are concentric and balanced. Make sure that all connections are tightened properly and there is no leakage.

Operation: Before starting the pump, check whether all parts are normal, whether there is leakage of water or gas, whether the oil level is normal, and whether the temperature and pressure are within the allowable range. During operation, regularly check whether there is abnormal noise or vibration, whether there is leakage of water or gas, whether the oil level is normal, and whether the temperature and pressure are within the allowable range. If there is any problem, stop the pump immediately for inspection and repair.

Maintenance: Routine maintenance should be carried out regularly to ensure that the pump is in good condition. Check whether there is wear or damage to the pump parts, especially to the contact surface between the impeller and liquid ring, and replace damaged parts if necessary. Clean and inspect all connections to ensure tightness and prevent leakage. Replace lubricating oil regularly to ensure good lubrication of pump parts.

The applicable temperature range of 2BV liquid ring vacuum pump is suitable for different environments

The temperature range of 2BV liquid ring vacuum pumps depends on the materials and design of the pump, as well as the operating conditions. Typical temperature ranges for 2BV pumps are between -20°C to +80°C. However, some models may have a wider temperature range, allowing them to operate in environments with temperatures below -20°C or above +80°C.

2BV liquid ring vacuum pumps are designed to operate in various environmental conditions. They can be used in both indoor and outdoor applications, provided that the pump is properly protected from adverse weather conditions such as rain, snow, and direct sunlight. Pumps should also be installed in a location that provides good ventilation and is free from dust, dirt, and other contaminants that may affect pump performance.