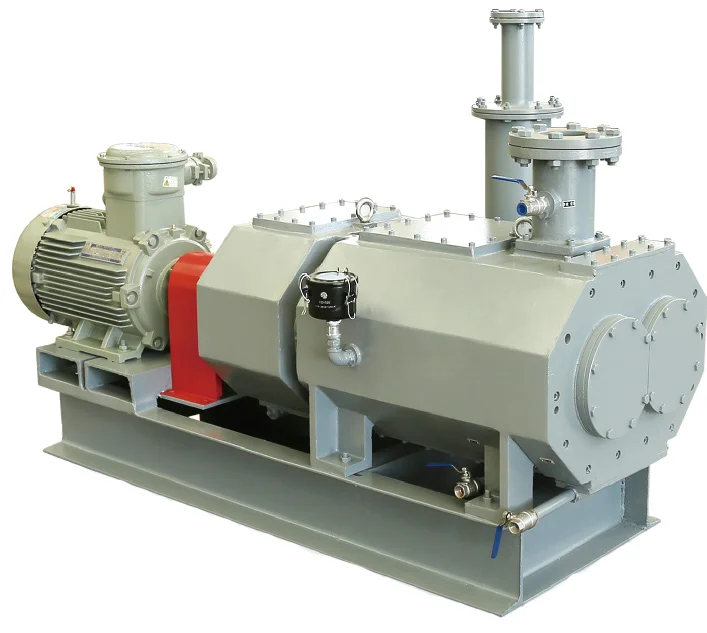

Among many issues that may arise in a vacuum pump system, the need for repair and servicing of a screw vacuum pump can be quite common. In such scenarios, understanding the guidelines for effective repair and maintenance is crucial.

When Might You Face Issues with Screw Vacuum Pumps?

Several situations can lead to problems with screw vacuum pumps, including improper installation, lack of regular maintenance, or the natural wear and tear that comes with prolonged use. Additionally, external factors like temperature fluctuations or the presence of corrosive or abrasive substances can also contribute to the degradation of the pump’s performance.

Solutions to Issues with Screw Vacuum Pumps

Regular Maintenance

One of the best ways to prevent issues with your screw vacuum pump is through regular maintenance. This includes cleaning, checking for any signs of wear and tear, and replacing any damaged parts as necessary.

Professional Servicing

If problems persist despite regular maintenance, it may be necessary to enlist professional help. This could involve hiring a technician who is trained and experienced in servicing screw vacuum pumps.

Replacement

In some cases, if the pump is too damaged or old, the best course of action may be to replace the entire unit. This should be considered a last resort, as it can be a costly solution.

Steps to Take When Facing Issues with Screw Vacuum Pumps

Should you encounter issues with your screw vacuum pump, the first step is to diagnose the problem. This may involve inspecting the pump for physical damage or testing its performance. Next, depending on the severity of the issue, you should decide whether to attempt a repair, call in a professional, or replace the unit. Lastly, always ensure to take measures to prevent future issues, such as sticking to a regular maintenance schedule.

What to Keep in Mind

When dealing with issues related to screw vacuum pumps, it’s important to remember that safety should always be your first priority. Always make sure to disconnect the pump from its power source before attempting any repairs. Additionally, remember to use the correct tools and follow the manufacturer’s instructions when servicing the pump.

How to Confirm the Problem Has Been Resolved

Once the repairs or servicing has been completed, the best way to confirm that the issue has been resolved is to test the pump’s performance. If the pump is working as expected and the issue does not reoccur, you can be confident that the problem has been successfully resolved.

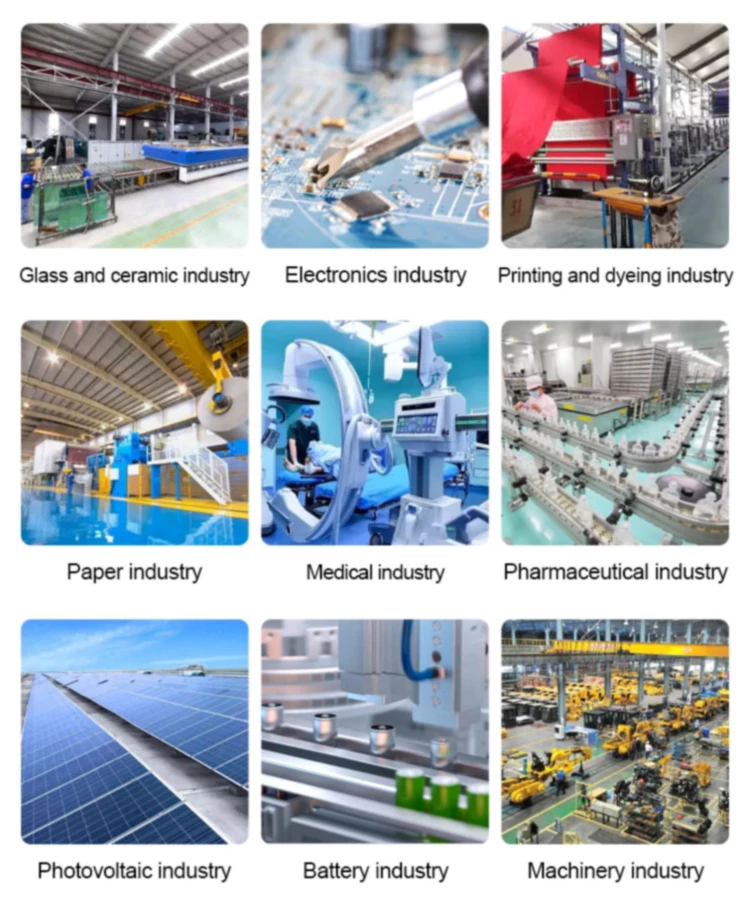

EVER-POW is a leading name in the Chinese vacuum pump market, offering a range of products including screw vacuum pumps, rotary vane vacuum pumps, roots vacuum pumps, rotating piston vacuum pumps, and our new model of rotary vane vacuum pump. We pride ourselves on our quality products, competitive prices, and excellent service. We also supply the 2be series water ring vacuum pump, 2bva series water ring vacuum pump, rotary drilling rig oil cylinder, liquid (water) ring vacuum pump, belt drive 2X rotary vane vacuum pump, low position steam jet vacuum pump, water jet vacuum system, and air-cooled Roots pump. We welcome customers to customize their orders based on their needs.

Q&A

- Q: How often should I service my screw vacuum pump?A: This depends on how often the pump is used and the conditions it operates in. However, a general rule of thumb is to service it at least once a year.

- Q: What should I do if my screw vacuum pump is not working properly?A: First, try to identify the problem. If you can’t, or if the problem persists, consider calling a professional for help.

- Q: Can I replace parts of my screw vacuum pump, or do I need to replace the whole unit?A: In many cases, replacing a faulty part can solve the problem. However, if the pump is old or severely damaged, it might be more cost-effective to replace the whole unit.

- Q: How can I prevent future issues with my screw vacuum pump?A: Regular maintenance is key. This includes cleaning the pump and checking it for signs of wear and tear.