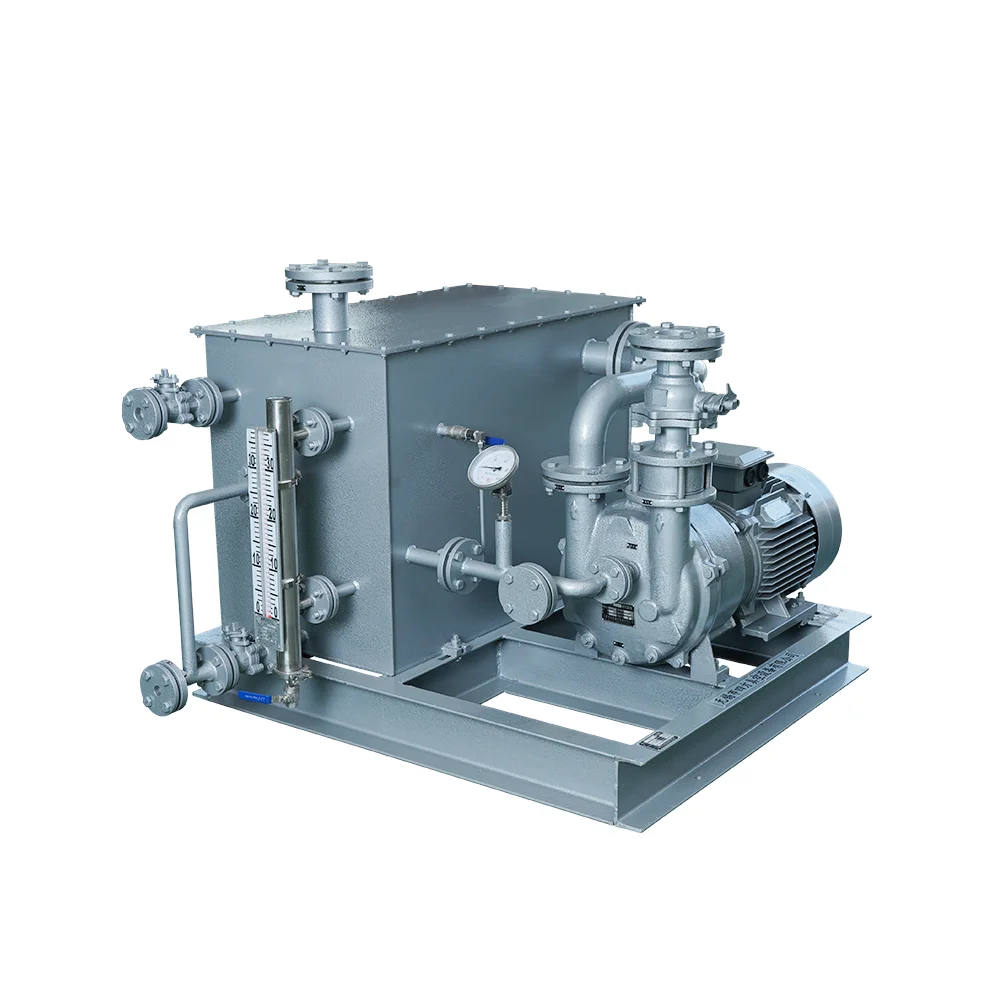

Professional Supplier Building Materials Electric 2 Stage Vacuum Air Pump Unit

2BV liquid ring vacuum pump is mainly composed of pump body, rotor, impeller, suction port, exhaust port and other parts. Among them, the rotor and impeller are usually integrated and are called eccentric rotors. When the rotor rotates, the eccentric rotor drives the impeller to rotate in the pump chamber, forming a liquid ring similar in shape to the pump chamber. The volume of the liquid ring changes as the rotor rotates, thereby completing the process of gas suction, compression and discharge.

The maintenance and repair steps for 2BV liquid ring vacuum pumps include the following:

-

Regular inspection: Regularly inspect the pump to check for any damage, wear, or leaks. Look for any signs of unusual noise or vibration that may indicate a problem.

-

Oil level check: Regularly check the oil level in the lubrication system. Make sure that the oil level is maintained at the correct level to ensure good lubrication and to prevent bearing damage.

-

Replace worn parts: If any parts of the pump, such as the impeller or liquid ring, show signs of wear or damage, they should be replaced promptly to prevent further damage to the pump.

-

Cleaning: Regularly clean the pump to remove dust, dirt, and other contaminants that may accumulate on the pump parts. Use a suitable cleaning agent and follow the manufacturer's instructions for cleaning.

-

Repair and overhaul: If the pump needs major repairs or overhaul, it should be taken to a qualified repair shop or the manufacturer's recommended service center. Do not attempt to repair or disassemble the pump yourself unless you have the necessary skills and experience.

To prolong the life of 2BV liquid ring vacuum pumps, follow these tips:

-

Regular maintenance: Routine maintenance is essential to keep the pump in good condition. Follow the manufacturer's recommended maintenance schedule and perform all necessary inspections and repairs promptly.

-

Proper installation: Ensure that the pump is installed correctly according to the manufacturer's instructions. Make sure that there is no vibration or stress on the pump during operation, and that all connections are tightened properly.

-

Operating conditions: Ensure that the pump is operated within the recommended temperature and pressure ranges. Do not operate the pump beyond its rated capacity, and provide sufficient cooling to prevent overheating.

-

Quality of water and lubricating oil: Use high-quality water and lubricating oil recommended by the manufacturer to reduce wear and corrosion on pump parts.

-

Regular inspection of water ring: Check the water ring regularly to ensure that it is in good condition and free from wear or damage. Replace the water ring if necessary to maintain good sealing performance.

Corrosion resistance of 2BV liquid ring vacuum pump

The corrosion resistance of 2BV liquid ring vacuum pumps depends on the materials used in their construction. Pumps made of corrosion-resistant materials, such as stainless steel or high-grade carbon steel, offer good resistance to corrosion and are suitable for use in corrosive environments. On the other hand, pumps made of less corrosion-resistant materials, such as cast iron or low-grade carbon steel, may be prone to corrosion and require more frequent maintenance and replacement of parts.

In general, 2BV liquid ring vacuum pumps are designed to withstand mild corrosive conditions. However, if the pump is exposed to highly corrosive substances or acidic/basic solutions, it may require special corrosion-resistant coatings or materials to protect the pump parts from corrosion. It is essential to consult the manufacturer's technical specifications and recommendations for specific corrosion resistance properties of the pump model being used in a particular application.