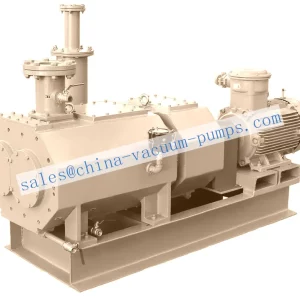

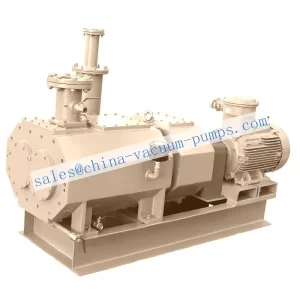

Screw Vacuum Pump

What is Screw Vacuum Pump?

A screw vacuum pump is a pump that uses a screw rotor to rotate and compress in the pump chamber to transport gas. Its working principle is that through the rotation of a pair of screw rotors, the gas in the pump chamber is compressed and discharged, thereby achieving air extraction and exhaust. Screw vacuum pumps have the advantages of simple structure, easy maintenance, and high reliability, so they have been widely used in the industrial field.

The characteristics of screw vacuum pumps include high pumping rate, low ultimate vacuum, low energy consumption, etc. It can be used in vacuum applications in various processes, such as pharmaceuticals, fine chemicals, new materials, oil and gas recovery, VOC exhaust gas treatment, environmental protection, food and beverages, starch sugar making, vegetable freeze-drying and other fields. At the same time, the screw vacuum pump can also be used in conjunction with other vacuum equipment, such as Roots vacuum units, oil diffusion vacuum pumps, etc., to achieve a more efficient vacuum system.

The screw vacuum pump has a compact structure, high efficiency, high reliability and easy maintenance. When selecting a screw vacuum pump, you need to consider its working pressure, flow, temperature, medium and other parameters, as well as its installation and operating environment and other factors. In addition, in order to ensure the stable operation of the screw vacuum pump and extend its service life, regular inspection and maintenance are required, and attention should be paid to keeping the pump clean and dry.

High Quality Screw Vacuum Pump for Sale

-

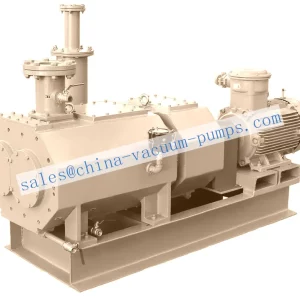

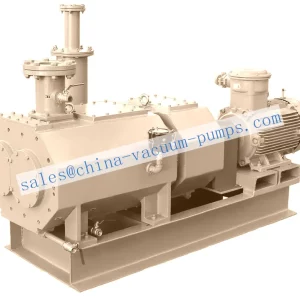

LGB Air Cooled No Oil Dry Screw Vacuum Pump Oil Less Dry Screw Vacuum Pump

-

Factory Price Industrial Screw Vacuum Pump Stainless Steel Single Vacuum Screw Pump

-

Hot Selling Screw High Pressure Vertical Vacuum Screw Pump Dry Screw Vacuum Pump

-

Professional Precision 200 Pumping Speed IP55 Protection CNC Oil Dry Screw Vacuum Pump

-

One Year Warranty LGB-300 50HP 300L/S Variable Frequency Electric Screw Vacuum Pump

-

New Energy Saving Environmental Product Air-cooled Oil-free Industrial Screw Vacuum Pump

-

Wholesale Portable Speed Adjustable Multi-stage Vacuum Systems Oil-free Screw Vacuum Pump

-

Support After-sale Service Multi-stage Screw Vacuum Systems Pump Electric Screw Vacuum Pump

-

Factory Price Industrial Double Stage Screw Vacuum Pump Oil Free Screw Vacuum Pump

-

IP55 Protection Customizable Screw Vacuum Pump Low Pressure Electric Brake Dry Screw Vacuum Pump

-

Sifang Vacuum Equipment Customized LGB-300 2 Stage Dry Type Oil-free Screw Vacuum Pump

-

OEM ODM Customized Industrial Oil-Free Air Cooling Electric Brake Screw Vacuum Pump

Typical applications of screw vacuum pumps

High reliability: The screw vacuum pump has less wear between the rotor, bearings, and seals, so it has high reliability and long service life.

Low maintenance cost: Because the screw vacuum pump has a simple structure and fewer parts, maintenance is relatively simple and the cost is low.

High pumping rate: The screw vacuum pump has a large pumping area and high rotation speed, so it has a high pumping rate and can meet the needs of various applications.

Low energy consumption: The screw vacuum pump has high efficiency and low energy consumption, which can help companies save energy costs.

Wide range of applications: Screw vacuum pumps can be used in various application scenarios, such as the chemical industry, pharmaceuticals, food processing, plastics, and other fields.

Easy automation integration: The screw vacuum pump is easy to integrate with automation equipment, enabling remote control and monitoring, improving production efficiency, and reducing labor costs.

Typical applications of screw vacuum pumps

Chemical and Pharmaceutical Industries: Used for processes like drying, distillation, and reactor service where clean, oil-free vacuum conditions are critical to prevent product contamination.

Food Processing and Packaging: Essential in vacuum packaging to extend the shelf life of food products. Also used in freeze-drying processes where maintaining a clean environment is crucial.

Electronics and Semiconductor Manufacturing: Employed in processes like vacuum coating, sputtering, and etching, where an oil-free and stable vacuum environment is vital for product quality.

Paper and Printing Industries: Utilized in paper de-watering and drying processes, as well as in printing for holding and moving paper.

Medical and Healthcare: Applied in sterilization processes and in the manufacturing of medical devices where contamination-free conditions are a must.

Environmental Applications: Used in soil remediation and vapor extraction processes where an oil-free vacuum is necessary to avoid contaminating the environment.

Central Vacuum Systems: Common in large facilities for various simultaneous vacuum needs, offering a centralized, reliable, and efficient vacuum source.

Custom Design

As a service to our customers, we offer extensive manufacturing experience and talent to meet the special needs of custom parts. Our in-house engineering team has extensive experience in designing and custom engineering solutions to meet your requirements. If you don’t see what you’re looking for in our standard range, please inquire about custom options.