How Does A Screw Compressor Work?

A screw compressor is used where a large volume of high-pressure air is required and these types of compressors are the masters behind most of the manufacturing industry. Screw compressors permit you to get a reliable compressed air source.

The industrial screw compressors can work 24/7 with no break and functions better with the long-lasting feature when it is used in that way. But comparatively, a piston compressor works better when it gets a break.

The rotary screw compressor can go all day with no break.

A standard screw air compressor has two interlocked helical rotors that are contained within a chamber. The air comes in through the valve and accounts the space between the rotor. When the screws spin, they decrease the volume of the air, at the same time which increases the pressure.

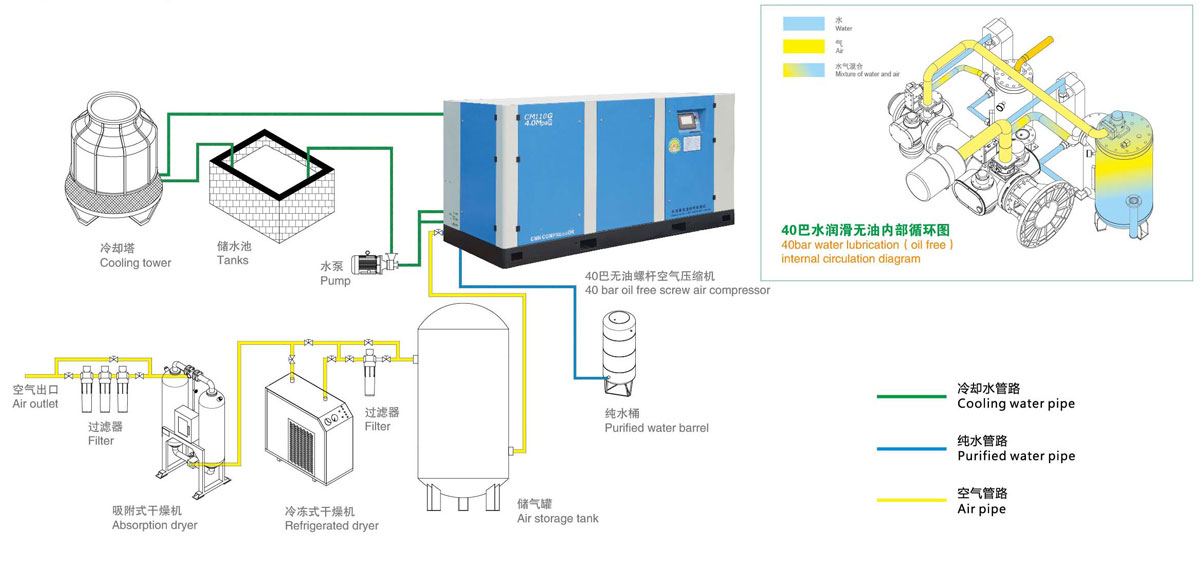

Rotary screw compressors can be two types: oil-injected and oil-free. But the twist is oil-free compressors don’t provide oil-free air, the difference is there is no oil in the oil-free compressors chamber.

In an oil-injected screw compressor, the primary rotor is drive by the engine and the secondary rotor is driven by the lean film between it and primary rotor. The oil locks the compression chamber or housing and functions as a coolant.

The oil-free screw compressor involves a set of gears which control the clock between the primary and secondary rotor(male and female rotor). As there is no oil to lock the chamber, so without several stages you cannot achieve high pressure same as oil-injected screw compressor. For these reasons, oil-free rotary screw compressors are restricted to special applications.

If you are interested to know more about the screw compressor, China Vacuum Pump is a specialist in air compressors. Call on 0086-571-87870085 to find out more.