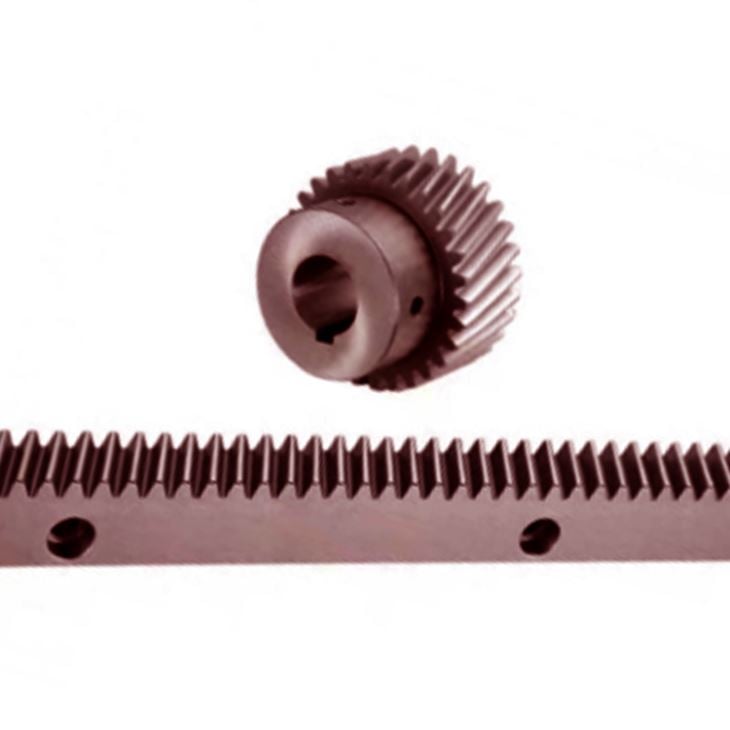

Our solution selection involves all types of helical gear, spur equipment, bevel equipment, gear rack, worm equipment, sprockets,chains, bearings, pto shaft, agricultural gearboxes.

Overview

Rapid Information

- Applicable Industries:

-

Producing Plant

- Regional Support Location:

-

None

- Surface Therapy:

-

Blacking, Sharpening, Anodization, Chrome Plating, Zinc Plating

- Warmth treatment method:

-

Quenching & Tempering, Carburizing & Quenching

- Standard:

-

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009

- Yr:

-

2014-2016, 2014-2015, 2010-2016ear:

- Tolerance:

-

Based mostly on drawing Size Dimension

- Specification:

-

In accordance to the the drawing

- model:

-

CT660, X-BOW

Provide Capacity

- Supply Capacity:

- 5000 Piece/Parts for every Thirty day period

Packaging & Delivery

- Packaging Details

- Neutral paper packaging, wooden packing containers for outer box or in accordance to customer’s demand.

- Port

- Shanghai / Ningbo

-

Lead Time

: -

Quantity(Pieces) one – one thousand >1000 Est. Time(times) 15 To be negotiated

Online Customization

We At any time-Electricity Team with 4 branches above 1200 workers is 1 of the biggest transmission elements and machining products producers in China

Solution Description

custom large high quality driving straight helical spline equipment stainless metal shaft

(1). All types of gears, shaft, gear shaft, precision gear and CNC gear.

(2). Specialised in producing all varieties of automobile transmission element primarily based on drawings

(three). Substance: ductile cast iron, carbon metal, alloy steel , stainless steel, , bronze/brass

(four). Modules: M1 to M8

(5). Fulfills ISO, DIN and ASTM standards

(6). Specification : In accordance to the the drawing

|

Substance |

Carbon Steel |

SAE1020, SAE1045, Cr12, 40Cr, Y15Pb, 1214Letc |

|

Alloy Steel |

20CrMnTi, 16MnCr5, 20CrMnMo, 41CrMo, 17CrNiMo5etc |

|

|

Brass/Bronze |

HPb59-one, H70, CuZn39Pb2, CuZn40Pb2, C38000, CuZn40etc |

|

|

Tolerance Control |

Outer Diameter |

Based on drawing |

|

Duration Dimension |

Based on drawing |

|

|

Machining Process |

Gear Hobbing, Gear Milling, Equipment Shaping, Gear Broaching, Gear Shaving, Equipment Grinding and Gear Lapping |

|

|

Enamel Precision |

DIN Course 4, ISO/GB Course 4, AGMA Class 13, JIS Course |

|

|

Modules |

one., one.25, one.five, 1.seventy five, two., two.25, 2.5….8. and so on |

|

|

Warmth Treatment |

Quenching & Tempering, Carburizing & Quenching, Substantial-frequency Hardening, Carbonitriding |

|

|

Floor Treatment |

Blacking, Sprucing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

|

|

Standard |

one. DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

|

Packaging & Shipping